Whenever I watch TV, listen to the radio, or even just look at billboards on the street, I’ll see an advertisement promoting how reliable a product is compared to its competitor. Everyone from car companies to tool companies to semiconductor companies tries to prove that they are the only company whose products you can truly trust and depend on. With so much of a marketing focus on reliability, clearly it’s an important issue. But what does it really mean to be the most reliable out there?

The most basic definition of reliability is the consistency of the measure. If you can consistently produce the same result under the same conditions, then the product is reliable. Simplicity is also an important factor. Reducing the number of parts in a system reduces the risk of one component malfunctioning and negatively impacting performance. For example, in the auto industry, a major concern is the reliability of the internal combustion engine. The functionality of the engine depends on perfectly timed interactions of hundreds of moving parts, so reliability is very important to ensure that cars run properly for 10+ years. Similarly, in the world of power electronics, most DC/DC converters rely on external components to configure the device and achieve the performance that the customer needs. However, every extra external component needed adds additional risk into the system.

Since reliability and simplicity go hand in hand, it is no surprise that the simplest parts to design also tend to be highly reliable. That is because simpler products have reduced bill-of-material (BOM) counts and integrate as many external components into the chip as possible. A high level of integration has several advantages, including reduced BOM count and cost, reduced board space, reduced design work, and higher reliability. The trade-off of high integration is a loss of flexibility. Converters like the TI LM5575 shown in Figure 1 require 12 or more external components to configure features and optimize the DC/DC regulator design to give the best performance for a particular application. Unless the application has particularly stringent requirements, however, the extra work and risk may not be worth it. Would you rather put in the work to complete a complicated design with 14 external components or buy a simpler product with higher reliability?

Figure 1: LM5575 schematic

One way to achieve low BOM count and increase reliability is to integrate the compensation network inside the integrated circuit (IC). Compensation networks are a necessary part of power IC design in order to ensure a stable loop response. Traditionally, power engineers have designed external compensation networks. The advantage of an external compensation network is the flexibility to freely select components and optimize the design to achieve a faster transient response. But designing the compensation is a complex, painstaking process. If you are a power expert with plenty of time, it’s no problem. If you are working under a deadline or do not have the necessary expertise, you may not have the time to properly design an external compensation network. If that’s the case, internal compensation greatly reduces the number of steps and risk in a power IC design. An internal compensation network minimizes the risk of faulty components or a mistake in the design that could negatively affect the end equipment’s performance. It also reduces the time it takes to design the power platform.

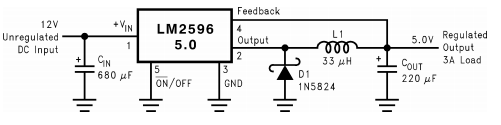

Another way TI increases reliability is by offering fixed-output-voltage versions. If you need the flexibility of programming the output voltage, we do have adjustable output options. However, the majority of TI’s customers use buck converters to power 24V, 12V, 5A or 3.3V rails off a battery. Offering fixed-output versions at these voltage levels provides several advantages, including decreasing BOM count, increasing reliability, improving the voltage accuracy of the output, and decreasing output noise. For example, in Figure 2, the LM2596 requires only four external components to function.

Figure 2: LM2596 schematic

The LM257x, LM259x and LM267x family of products have the lowest BOM count of any SIMPLE SWITCHER® DC/DC buck regulators. By designing our products with simplicity and reliability in mind from the ground up, we are able to reduce the external BOM count needed from 11 components down to four or five components. Every external component that TI can eliminate or integrate inside of the chip has the additional advantage of increasing product reliability while also reducing the amount of design work needed. Make your life easier and choose a buck converter that you can really trust.

Explore our SIMPLE SWITCHER devices to jumpstart your design.

Additional resources

- Search for SIMPLE SWITCHER devices that meet your design criteria, and sort the results by low component count.

- Get more information on the LM2596 and other SIMPLE SWITCHER regulators with low BOM count requirements.