Electric vehicles (EVs) are an unavoidable topic when discussing modern transportation. Coming from Germany, a country that takes pride in their automotive history, the EV market is growing fast. I would consider buying an electric car in the near future, as would many others.

According to several forecasts, the market for EVs will increase dramatically, from 500,000 in 2015 up to 41 million by 2040. The global governmental growth target is even higher: 100 million electric cars and 400 million electric two- and three-wheelers on the streets by 2030.

Two of the key considerations when buying an EV are charging time and maximum range. Long charging times and the lack of an existing DC charging infrastructure are drawbacks for many potential consumers. With the rapid growth of this market also comes the rapid development of fairly substantial integrated onboard chargers (one to six hours) and fast charging piles (10-30 minutes).

Let’s go deeper into some definitions and characteristics of the two different charging systems: onboard chargers and fast charging piles.

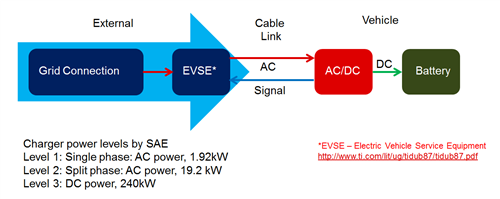

An EV or hybrid electrical vehicle (HEV) uses onboard chargers to convert line current (50/60Hz AC) to DC and to provide an isolated DC output to charge the traction battery, as shown in Figure 1.

Figure 1: High level system block diagram- on-board charger

An EV usually consists of two lead-acid batteries operating at 12V and 48V, and one lithium-ion (Li-ion) battery operating at a higher voltage of around 400V. The two lead batteries support the starter and internal systems, while the 400V battery serves as the energy source for driving.

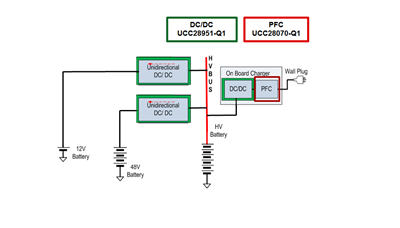

Onboard charger modules are normally two-stage converters: the input stage uses a power factor correction (PFC) module in the AC/DC power supply with a 400VDC output, which is then fed into the next stage, an isolated DC/DC converter, as shown in Figure 2. This provides galvanic isolation and a constant voltage and current output, which is necessary for efficient battery charging.

Figure 2: PFC and DC/DC controller for on-board charger

The unidirectional high- to low-voltage converters then charge the 12V and 48V lead-acid batteries from the 400V Li-ion battery’s high-voltage bus.

A fast charging pile has the same properties as an onboard charger module except that the PFC stage is off-board, driving a DC link up to 600V. This ability to reach a higher voltage is the reason why this system achieves faster charging times than the onboard system.

But what is PFC and why is it necessary? You can find PFC in isolated AC/DC power supplies, where it efficiently transmits energy from the power grid to the end system.The PFC draws an in-phase sinusoidal current from a sinusoidal source. This reduces the peak and harmonic currents and maximizes the power drawable from a given AC source – a household socket, for example. Usually any electric equipment that uses 75W or more from the grid is required to use PFC.

TI’s AC/DC solution for both charging systems is the UCC28070-Q1 interleaved continuous-conduction-mode PFC. The UCC28070-Q1 is an advanced PFC device that integrates two pulse-width modulators (PWMs) operating 180 degrees out of phase. This interleaved PWM operation substantially reduces the input and output ripple currents, enabling easier and less-expensive conducted electromagnetic interference filtering.

The isolated DC/DC function is best implemented with a phase-shifted full bridge (PSFB) and the UCC28951-Q1 as the controller. The PSFB works in high-voltage and high-power DC/DC applications where the output voltage varies over a wide range, as found in battery-charging applications. Furthermore, the zero-voltage-switching action of the PSFB significantly reduces switching losses in the primary-side metal-oxide semiconductor field-effect transistors (MOSFETs), enabling potential efficiencies greater than 99%.

As the market for EVs continues to expand, so will TI’s development of products to support these charging solutions. Read the blog, “Pile on to a charger – my EV needs power” to learn about the subsystems that transfer large amounts of power at EV charging stations.